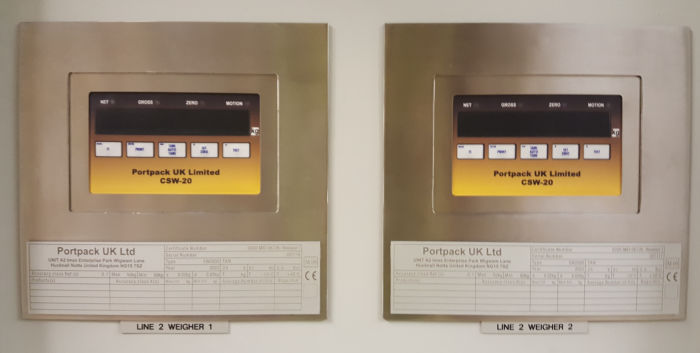

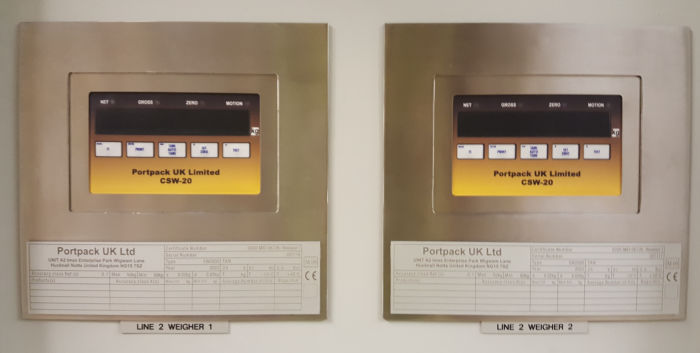

CSW-20 Controllers

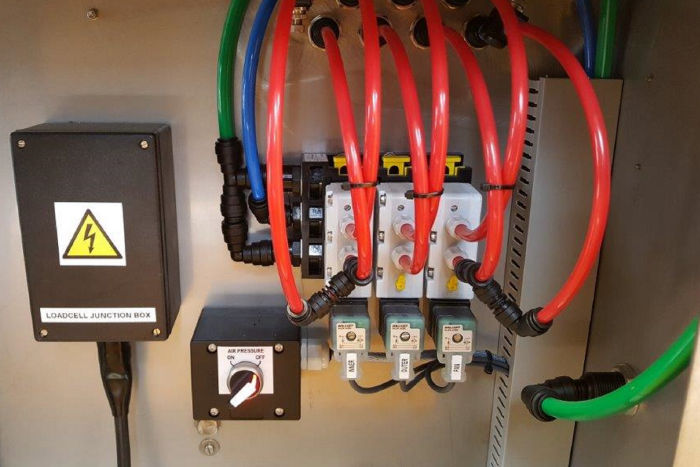

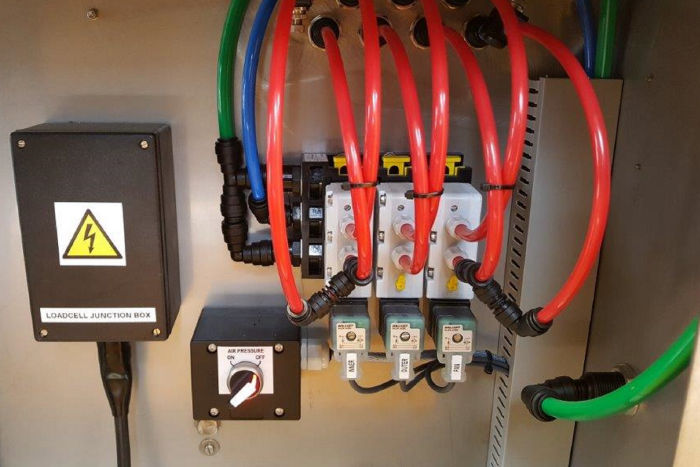

Junction Boxes

Make your own website in a few by th a

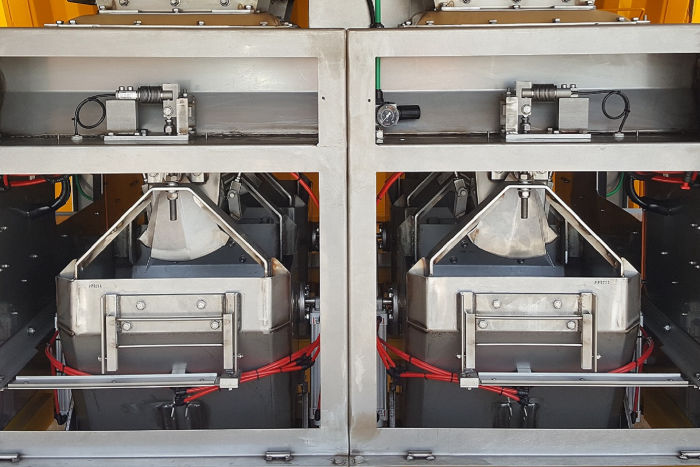

Portpack can offer the following service to up-date any Portpack equipment of mechanical design to electronic design, subject to a survey to determine the condition of the existing equipment.

The conversion will allow full loadcell weighing with Siemens controls and CSW-20 approved microprocessor self optimising controller.

The CSW-20 controller incorporates self optimising control for up to 12 products, this allows individual parameters to be set and stored for each different material and size of weighments. These settings include in-flight material compensation and tolerances.

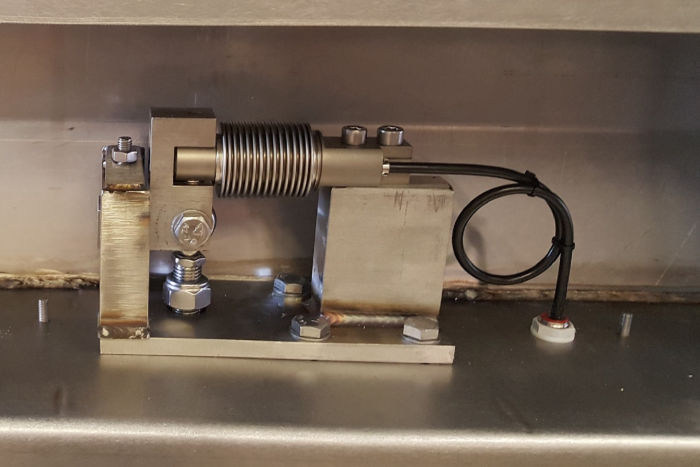

The two shearbeam loadcells on each weigher send a signal to the CSW-20 microprocessor controllers, which incorporate the optimising controls to enable weighment checks and self correction if necessary, this ensures all weighments are maintained to the set range and tolerances.

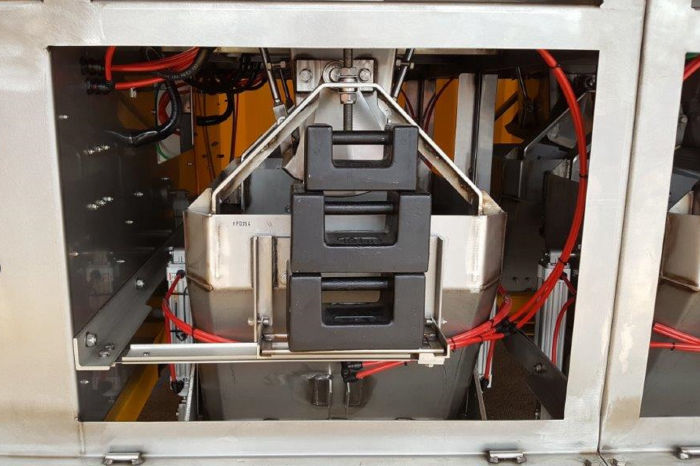

The weighpans are suspended on vertical connecting rods from each loadcell and incorporate weight racks for approved test weights to be mounted during calibration and set up. The weighpans are stablised by horizontal flexures to give accurate weighments and repeatability.

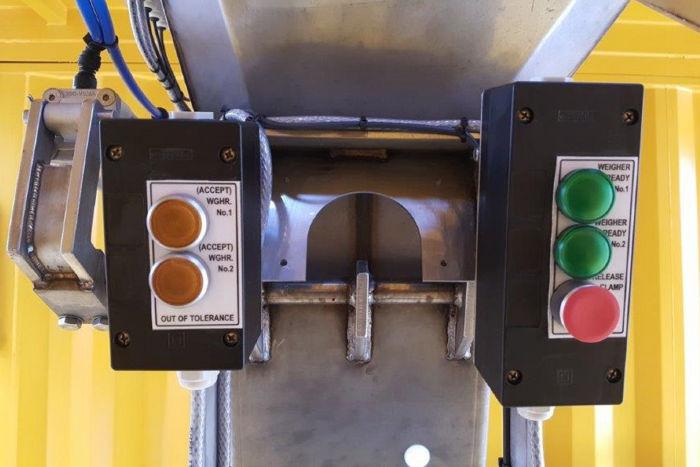

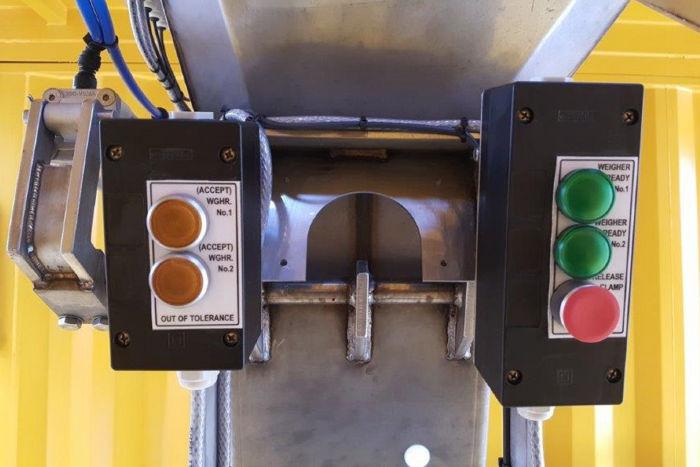

Operator controls with idicator light confirm which weigher weighment is ready for discharge and emergency stop for emergency bag release.

Operator tolerance station enables operator to accept an out of tolerance weighment when indicated by the microprocessor controller.